High agave prices aren’t the only factor driving up the costs of making tequila. Producers are pointing to a number of mostly pandemic-related issues that are making everything from sourcing bottles, printing labels, and shipping products more difficult and costly.

“Covid restrictions prevented many companies from operating for a period of time, and then many were granted (permission) to operate under certain restrictions, such as reduced staff and social distancing,” says Steffin Oghene, Vice President of Business Development at Tequila El Tequileño.

This has had a knock-on effect, and many tequila producers have had to source new suppliers due to a lack of availability, he adds.

Glass bottles are just one of the necessary supplies that are harder to come by, due to pandemic shutdowns and extreme weather in Texas, which stopped the gas supply to Mexico for a period of time, forcing some glass makers to cease operations. These factors led to a reported 40% decrease in glass production this year.

Another challenge facing almost every industry is the reduction in shipping routes and lack of cardboard boxes and containers to ship products in.

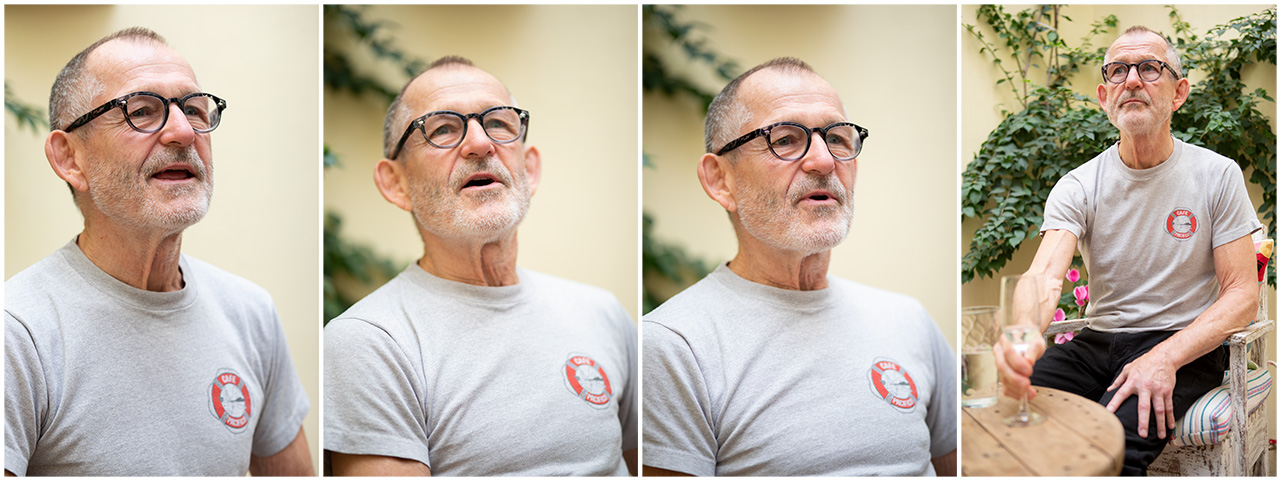

“Cardboard prices have doubled and we cannot find wooden pallets to ship our tequila. We had to buy plastic pallets,” says Felipe Camarena, Owner and Master Distiller at the El Pandillo distillery in Jesús María, Jalisco.

The cardboard shortage is being pinned at least in part on the abundance of online orders that were made during Covid lockdowns around the world, eating up existing supply.

As for pallets, lumber prices have increased in many countries as demand for new housing and remodels in the U.S. and elsewhere have soared.

Construction in the tequila region has also led to a shortage of distillery workers, according to Camarena, as agave producers, flush with cash thanks to sustained high agave prices, have moved to invest their gains in new homes and businesses.

Another unwelcome surprise for producers: the rising cost of copper, which is essential for making artisanal pot stills.

“Copper prices have gone up 85%, which makes increasing capacity amid high demand very expensive,” Camarena says.

He, like many other tequila producers, saw a surge in sales last year as consumers shifted from buying shots in bars to buying bottles for home. And the popularity of tequila still hasn’t abated. To ensure future capacity Camarena recently invested in a new 5,000 liter copper pot still, despite the soaring costs.

Faced with these across-the-board cost pressures it’s not surprising that some producers have raised their prices to compensate for their higher production costs. At the El Buho tequila store in Tlaquepaque, salespeople say that many brands have raised prices recently, some by as much as 20%.

Meanwhile, other brands like El Tequileño and Tapatio, have maintained their pre-pandemic prices, hoping life will be back to normal again.

But even as supply chains get straightened out, producers’ largest expense continues to be sourcing agave, which still stands at 27 pesos/ kilo.

“Our number one cost is still agave,” says Guillermo Erickson Sauza, owner of Tequila Fortaleza. “Ten years ago it cost us about US$1,875 to fill our small (15 ton) oven. Now, it costs us around US$22,500,” he adds.

While one might think that agave prices would come down during the pandemic, when retail outlets were closed, the unforeseen explosion in demand kept prices high.

Fortaleza’s other supply costs, such as for bottles and cardboard, haven’t risen yet because they are under contracts, Sauza added, but that could change soon.

Also ticking up some producers’ costs is a lack of mature agave (7+ years), which allows tequila makers to get a higher yield because mature agaves contain more sugar that can be converted into alcohol. Really sweet agave can make a substantial difference to producers’ bottom lines, allowing them to increase their yields by around 30%, says Sauza.

However, agaves aged 5 and 6 years are all that most distilleries have access to right now. Those last few years are when the plant produces the most sugar.

During a recent visit to El Pandillo, we saw Camarena inspecting cooked agave that recently came out of his oven. It was from his last field of fully mature agave. The piñas were dark with caramelization, and sweet agave juices dripped off the leaves as we tore off pieces to taste.

“This is really sweet. I should get a pretty good yield,” Camarena said. In these costly times, every bit helps.

Good Read

Very informative. Seems like the prices are down here in the states. As it should be since they started growing GMO agave a few years ago. Organic tequilas are real reasonable and people always spend money on what they want and like. People drink to celebrate and when they are depressed. It’s a win win for the producers

Can you cite your source for GMO agave use in tequila production? I’ve not heard that before. Gracias.

I’m not sure if GMO agave is being grown but, they have been cloning agave for some time now.

This is how fake internet news gets started. Thanks for calling Clay out on this one Remy!

Great read!

Steve made the statement, not Clay. It is important to see the big picture as not to perpetuate misinformation.

Excellent read. So many factors for the price in creases. Glass, cardboard, pellets, copper and of course the cost of agave.

I may understand why tequila prices have gone up. But, in Mexico, the bottles used to 1 liter, they still sell some, but

then they went down to 750 ml. And now you can only find any tequila in bottles of 700ml , and the price is even higher

Now you start seeing in USA bottles of 700ml

That seems to me like greed from the tequila makers. Do you have any ideas why is this happening?

J L Garcia

I’d rather pay more and keep the 750ml bottles or larger. I’m tired of everything shrinking. Whether producers intend to or not, it feels like they are gouging us.

From what I understand, 700 ml is the normal in Europe. The U. S. Recently passed legislation allowing liquor to be sold in 700 ml containers.

Easier for a producer to use 700 MLS and cover 2 major markets, rather than carry double inventory or have to decide based on bottle size

Thank you. This is helpful and I realize it’s not all about greed.

I’m just really bummed because I can’t source my favorite anywhere. Now I have to brace myself for the sticker shock when it does come back.

This last weekend I introduced a friend to Old Town Tequila here in San Diego, and was looking to replenish my Pasote Blanco (still a fan favorite) as well.

I was surprised to find that the distinctive Pasote bottle is now not quite so distinctive. It is now a simple clear bottle with a Pasote

printed label. While I will miss the look of the old bottle, I am in full support of Felipe being nibble with his business operations to keep prices down as much as possible.

Thanks Felipe for a delicious Blanco!

You should try Bandero, it’s has a beautiful hand blown glass bottle, it’s a Blanco and becoming known as the World’s best sipping tequila!

I haven’t tasted the product since it switched NOMs, but Pasote has flown the Destileria el Pandillo coop. It’s actively being made at El Tepozan. I have a first release expression of Pasote Blanco, it’ll be interesting to try the side-by-side.

I have always said “ During good times people drink in celebration “ in bad times people drink more because of depression. In the mean while, the grower is finally get his rightful pay and it should have been that way along time ago.

21 Seeds. Could anyone comment?

Are the current high agave prices impacting all producers, or just those who do not use 100% estate-grown agaves? I assumed some producers are using their own estate-grown agaves, and as such would not be impacted by the current high market rate.

Considering the exponential rise in new agave spirits in the market and the time it takes for agave to grow to maturity, did anyone predict this 10 years ago? No way. The mass produced brands backed by celebrities have contributed to this shortage and the compromising of quality tequilas and other agave spirits. Why support these low quality brands that are exploiting this precious resource? Do these already wealthy celebrities need any more money? Since when is anything mass produced of any quality?

Take a look at who owns this brands and what their practices are…they’re all profit driven, meaning they take shortcuts to maximize profits and putting pressure on a fragile ecosystem that may not ever recover from this cash grab.

Stop supporting the mass marketed garbage tequila that’s being marketing out there and support true native products like Fortaleza/Los Abuelos, Fuenteseca, Siembra Valles, Siete Leguas and others that don’t compromise quality.

Spot on !

Excellent analysis. I agree 100%

100%. I’m also not a fan of the cristelano fad. Several years ago it was only DJ70 and now it seems that every brand has one. The uninformed masses love the fad because the tequila sips “smoother” not realizing that they are sipping a stripped down repo or anejo.

Great article. Really appreciate the research that went into this! So many friends coming to me saying “I hear there’s not going to be tequila anymore!?” based off of some mainstream media headline and shock-seeking article. Thanks for giving me some facts to help explain what’s really happening.

I haven’t seen prices go up that much. I can still find good bottles of tequila here in Ohio for around $28. $35-$40 gets you an even better bottle. $50 if you’re trying to impress someone.

So this is the reason I can’t find/replenish my personal supply of Fortaleza’s Blanco?

Where can I find up to date prices of agave? And not just Blue Agave.

Hi Chris. Good question. We’re only tracking weber blue agave within the tequila denomination. I’m not sure there is a list like that anywhere.

I live in San Diego, CA and purchase my tequila across the border.

The prices for tequila have soared tremendously here in Tijuana, BC , post pandemic!!! Thanks for posting an informative article on the reasons why.